|

|

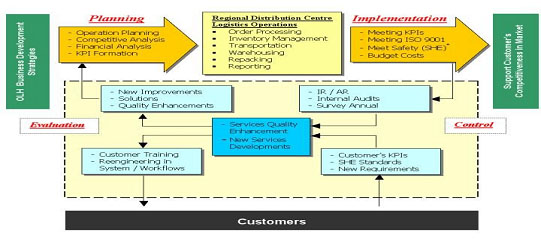

Executive Summary Asia-Pacific markets, particularly in Greater China, are very different from North American and European markets. Companies need to face complex supply chain issues such as multi-cultures, multi-languages, infrastructure inconsistency, complex business environments, and trade regulation variances. The emergence of China as a global factory and the fast growth of the domestic economy brings up new supply chain challenges for multinational companies, thus increasing Hong Kong’s role as the preeminent regional business center. Oriental Logistics, founded in 1997, began shaping the third party logistics (3PL) role in the Hong Kong and Greater China area together with a variety of multinational company partners to pioneer many innovative logistics service concepts. Customers of Oriental Logistics include multinational companies from United States, British, Germany, France, Japan, Hong Kong, and Taiwan. These customers serve many different roles in the supply chain, all with vastly different logistics requirements. Oriental Logistics works together with the customers to develop innovative approaches to create value in their supply chains. How can Oriental Logistics play a successful 3PL role in a highly competitive marketplace in Hong Kong and Greater China area? The answer lies within what Oriental Logistics believes and practices, which serves as the foundation for the Customer Partnership Mechanism. 3PL as a Young Supply Chain Profession in the Orient Firms are outsourcing logistics activities and upgrading relationships with 3PL companies from transactional to tactical and strategic decisions. A 2005 industry survey indicated that CEOs of 3PL companies operating in the Asia-Pacific expected 17 percent average business growth through 2008. Third party logistics is an industry and profession quite developed in the Western world, but is very underdeveloped in Asia, especially in the Greater China area. In 1997, Oriental Logistics Holdings (OLH) incorporated in Hong Kong during a downturn of the Asian economy and the return of Hong Kong to Mainland China. In the beginning, OLH only provided warehousing services and limited transportation services in the marketplace. Subsequently, OLH grew into a third party logistics (3PL) provider with full logistics service capabilities in Hong Kong and the Greater China area with 300 employees and over USD 19 million dollars in revenue. Customer Partnership Mechanism The Customer Partnership Mechanism is a core innovation of Oriental Logistics. This mechanism is part of every logistics project, or it can be better interpreted as one of the major processing tools in the management. All activities undertaken can be classified into four steps, which are Planning; Implementation; Control & Evaluation in a cycle process. |

|

|

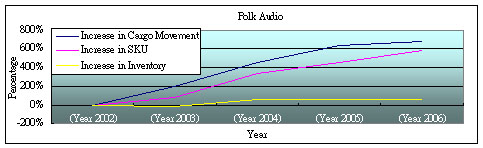

OLH Customer Partnership Mechanism Planning – It starts off with planning to determine the steps to ensure the major elements are set. (see above diagram) For all new projects, the performance costs and sales budgets for operation are outlined for team members to follow. The team can understand in what ways to best serve the customer. Implementation – In the implementation stage, the team lead is asked to follow the objectives, KPIs, cost and revenue budget as established in the beginning. Their related skills, logistics management experience and attention to details will determine how well they accomplish the project. Most importantly, there is customer knowledge transferred to the front line. Handling techniques and safety requirements are very strict. Staff is technically trained for the specific needs of each item. All precautions and safety requirements stated in the Material Safety Data Sheet (MSDS) are passed onto the staff members responsible. Control – After the implementation stage, our internal auditors will list out all the KPIs and service standards on a checklist to follow them up with a physical audit to the physical operation, and ensure that every KPI and standards are strictly followed. The audit then would extend to a financial evaluation to find out if project is profitable or not. From the customer side, a few inputs will be obtained such as from the Annual Customer Survey. There is also feedback from customers. By doing this, valuable input on quality enhancement can be gained. Evaluation – Direct reports on special issues reach the corporate management and are reacted upon swiftly. Hence, valid improvements can be made fast. Finally, new measures, improvements or new service will be suggested in accordance with evaluation & investigation results. Under the Customer Partnership Mechanism, the service quality and the operation productivity can be continuously improved. Problems are reduced significantly. We meet customer requirements and can enhance or create new service offerings in a continuous quality enhancement cycle, thus maintaining a smooth partnership. CASE STUDY : POLK AUDIO Since 1972, Polk Audio has been producing home and mobile audio equipment. Its product offerings range from speakers, amplifiers, satellite radios, HD Radios and iPod -compatible audio products. Polk Audio operates manufacturing plants in China and Vietnam for their Asia-Pacific sales distribution. In order to exert high control over its value chain by minimizing the total logistics costs within the supply chain, Polk Audio required a logistics provider able to manage the communications along its vertical supply chain and distributor network. Oriental Logistics became the 3PL provider for Polk Audio’s Asia-Pacific region in 2002. Oriental performs the functions of the logistics hub in the Asia region and operates that manages the import/export shipments. With its expertise in combining logistics with information technology, Oriental helps to coordinate with Polk Audio’s tiers of manufacturers for the storage of import shipment and forwarder networks for handling export order fulfillment. It has been able to provide instant inventory visibility and fast track of shipment status by offering its online platform: WIS (Web Information System), allowing Polk Audio to run logistics operation in the Asia-pacific region without setting up any local branch in Hong Kong. Apart from general warehouse operations, Oriental also provides various kinds of value-added services customized for Polk Audio. With the help of Oriental, Polk Audio is able to concentrate on its core competencies of sales and product development and plan ahead for the inventory forecast. As a result, there are 5.8 times more in sales items with only 50 percent increase in inventory (see diagram below). In addition, Oriental helps to reduce replenishment time and improve the warehouse throughput, which contributes to the dramatic increase in stock turnover. |

|

|

CASE ONE: Ongoing Supply Chain Innovation |

|

Conclusion Oriental Logistics Holdings (OLH) has witnessed dramatic changes in the global marketplace, particularly in the Greater China region. Fierce competition and the adoption of advanced supply chain management models have resulted in global firms upgrading logistics service standards for their buyers and at the same time requiring 3PL providers to support these challenging initiatives with innovative solutions. The Customer Partnership Mechanism is the centerpiece of OLH’s innovations in supply chain management. We are always refining the process of obtaining customer feedback to provide continuous service improvements with new service offerings and quality enhancements. The product of our innovation is by our e-platform tool, which gives all logistics related data and information on the web for reporting, or a direct enterprise resource planning (ERP) system linkage as an option for real time information exchange. The evolution of the supply chain partnership model allows OLH to implement many supply chain innovations to face up to the challenges of continuing stringent customer requirements. The Polk Audio example demonstrates how the continuous customer services improvements in the customer-centric supply chain partnership model achieved measurable results. OLH customers are experiencing significant business growth in the region, with more variety of stocks to supply and more efficient and effective delivery to buyers. As a result, OLH customers can focus on their core specialties with the knowledge that their every logistical need has been taken care of by Oriental Logistics.

|

Customer Enquiry HotlineTEL: (852) 2541 3337

Business Results On Better Supply Chain Partnerships