|

Oriental Logistics provides logistics services to a major American manufacturer of adhesive films, coatings, and specialty films. The customer needed another 3PL to support their RDC operations based on their unpredictable business growth. Their requirements were that the new 3PL must operate in full scale before the peak season started, as their existing 3PL could no longer handle their growing requirements in space, system support and other resources allocations. Also, there were some operational details to be resolved. For example,

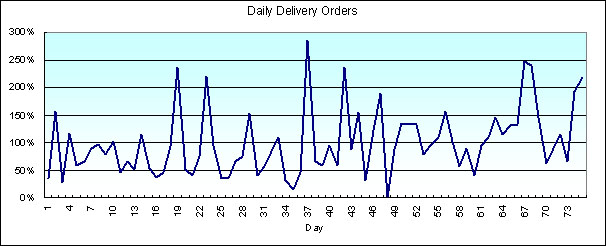

Diagram 8 indicates that the seasonal and daily demand variation were so large that regular review on the current requirements, short term, and long-term future requirements were needed so that appropriate action could be taken for the necessary resources. |

Diagram 8 Typical Daily Orders Fluctuation Pattern (average = 100%) |

|

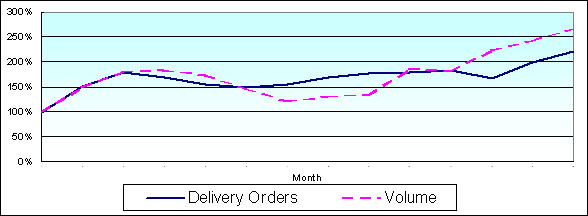

OLH found the urgent need of EDI linkage as a means to enhance the accuracy and lead-time. The IT Departments of the customer and OLH, made a test of EDI System Integration, which commenced in 3 weeks time. The EDI linkage was operational within one month after some fine-tuning. This ensured the direct updating of information without manual input. After OLH took over the customer’s logistics operations and improved the logistics and information flows, the growth of the customer’s business was very clear. Standard Operating Procedures (SOP) for both parties was regularly reviewed to enhance the overall logistics performance and to achieve a higher KPI standard. |

Diagram 9 Cumulative Orders and Volume Growth Rate |

The Customer Partnership Mechanism is the centerpiece of OLH’s innovations in supply chain management. We are always refining the process of obtaining customer feedback to provide continuous service improvements with new service offerings and quality enhancements. The product of our innovation is by our e-platform tool, which gives all logistics related data and information on the web for reporting, or a direct enterprise resource planning (ERP) system linkage as an option for real time information exchange. The evolution of the supply chain partnership model allows OLH to implement many supply chain innovations to face up to the challenges of continuing stringent customer requirements.

Our case studies demonstrate how the continuous customer services improvements in the customer-centric supply chain partnership model achieved measurable results. OLH customers are experiencing significant business growth in the region, with more variety of stocks to supply and more efficient and effective delivery to buyers. As a result, OLH customers can focus on their core specialties with the knowledge that their every logistical need has been taken care of by Oriental Logistics.

The Customer Partnership Mechanism is the centerpiece of OLH’s innovations in supply chain management. We are always refining the process of obtaining customer feedback to provide continuous service improvements with new service offerings and quality enhancements. The product of our innovation is by our e-platform tool, which gives all logistics related data and information on the web for reporting, or a direct enterprise resource planning (ERP) system linkage as an option for real time information exchange. The evolution of the supply chain partnership model allows OLH to implement many supply chain innovations to face up to the challenges of continuing stringent customer requirements.

Our case studies demonstrate how the continuous customer services improvements in the customer-centric supply chain partnership model achieved measurable results. OLH customers are experiencing significant business growth in the region, with more variety of stocks to supply and more efficient and effective delivery to buyers. As a result, OLH customers can focus on their core specialties with the knowledge that their every logistical need has been taken care of by Oriental Logistics.