|

Oriental Logistics has been providing logistics services to a world-wide specialty silicone company since 1997. Specialty silicones provide improved performance and unique properties to products in consumer and industrial markets. This customer company has technology centers and an extensive network of sales and service offices on five continents, supported by R&D and manufacturing facilities in the US, Canada, Switzerland, Italy, Germany, the Netherlands, the United Kingdom, Japan, the People’s Republic of China, Korea, Thailand and Brazil. Initially, Oriental Logistics entered a 3PL partnership with this company in a very small scale by providing warehousing services in the Greater China area. This 3PL relationship grew every year and became an RDC in Hong Kong with extended service scopes in order fulfillment, inventory control, transportation, freight forwarding, import/export, ERP EDI linkage, e-Ordering, etc, even under several major corporate mergers and acquisitions. The ongoing growth of the customer has created many challenges for Oriental Logistics. In the early stages, Oriental Logistics processed orders in pallet sizes delivered to limited locations. However, due to the market changes and the sales growth of the customer, Oriental Logistics now processes orders in cases and broken cases that are bound for many locations in the region. Almost every order needs extra re-labeling and re-packaging value-adding tasks to be performed. In 2006, nearly 90 percent of export shipments were repacked before delivering to the customer. Oriental Logistics is able to provide an online platform for accessing a variety reports such as an inventory key performance indicator (KPI) report for controlling stock inventory performance, delivery status report for real time checking of deliveries. The complexity of global logistics operations in recent years caused Oriental’s ERP and the customers’ SAP to connect with an EDI linkage. Based on the Customer Partnership Mechanism, the customer decided to start up the EDI linkage with Oriental Logistics. At the beginning, many adjustments were made to enhance the systems to be more user-friendly and consistent. Many benefits have been brought to the customer and OLH due to the automation and synchronization of logistics document flows. Firstly, data input costs are reduced. All inbound and outbound shipment information can be downloaded electronically from the customer’s SAP to Oriental ERP. The time saved can be used in other value-added services. Secondly, 100 percent accuracy in picking goods for delivery can be ensured. The SAP system will send out an acknowledgement through EDI linkage to make sure no human error happens during the whole process. When SAP data is checked and completely matched with Oriental ERP system, the ERP system will return back an EDI message to confirm acknowledgement. It is an interactive system linkage at each stage. Thirdly, the inventory level is now controlled in real time. Both goods issued (GI) and goods received (GR) are done in Oriental Logistics via EDI linkage. All data is transparent and can be assessed worldwide, Oriental also receives the updated information (i.e. new shipment’s products information, shipment date, loading port). The customer’s SAP can control and maintain stock within a safety level in real time. This benefits the customer to control logistics costs. All exchanged data is valuable for market planning and strategic vision. |

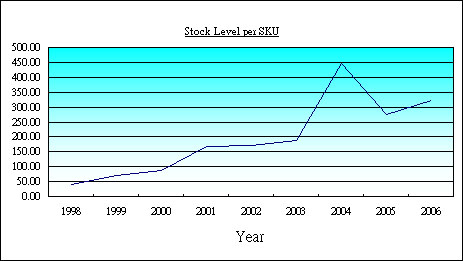

Diagram 6 Stock Level per SKU on every year-end |

| In Diagram 6, volume per total SKU is increasing, but surprisingly in 2005, the number dropped nearly one-third (SKU dropped by nearly one-fifth). The reason is since EDI linkage started, the customer can control inventory placed in 3PL warehouse facilities easily in real time to forecast the needs of goods with their customers. As a result, the performance improved on inventory controls, turnover rate of goods, and forecasting the needs of goods. |

The Customer Partnership Mechanism is the centerpiece of OLH’s innovations in supply chain management. We are always refining the process of obtaining customer feedback to provide continuous service improvements with new service offerings and quality enhancements. The product of our innovation is by our e-platform tool, which gives all logistics related data and information on the web for reporting, or a direct enterprise resource planning (ERP) system linkage as an option for real time information exchange. The evolution of the supply chain partnership model allows OLH to implement many supply chain innovations to face up to the challenges of continuing stringent customer requirements.

Our case studies demonstrate how the continuous customer services improvements in the customer-centric supply chain partnership model achieved measurable results. OLH customers are experiencing significant business growth in the region, with more variety of stocks to supply and more efficient and effective delivery to buyers. As a result, OLH customers can focus on their core specialties with the knowledge that their every logistical need has been taken care of by Oriental Logistics.